TEL: (074) 938-1178 | EMAIL: [email protected]

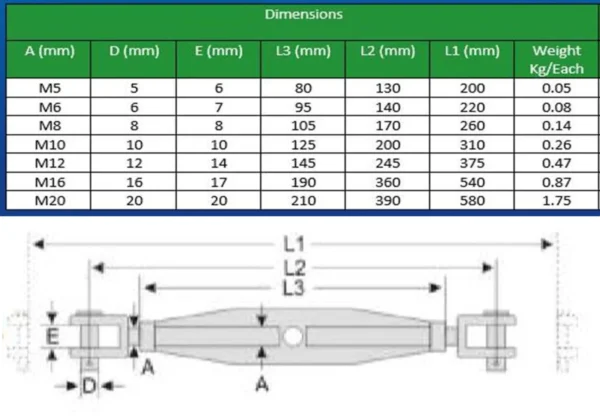

Stainless Steel Rigging Screws Jaw/Jaw

€7.50 – €13.50

- Polished Finish AISI 316 Marine Grade A4 Stainless Steel.

- Closed Body with a Jaw and Jaw or Fork and Fork, superior rust resistance.

- For fastening and binding rope. Simply take out the Clevis Pin from The Screw Fork by removing the Split Ring.

- Perfect equipment for adjusting tension on ropes, cables and lines.

- Each end has open jaw with pin and safety wire for easy, secure connections.

The ends are usually connected via a shackle, ferrule or wire grip to a wire rope. Once connected the body of the rigging screw, tensioner, turnbuckle or bottle screw can be rotated. This causes the overall length of the screw, tensioner, turnbuckle or bottle screw to shorten as the opposing threads of the threaded bar get pulled into the rigging screw, tensioner, turnbuckle or bottle screw. The result is a tensioned wire rope.

Not certified for lifting, Stainless finish.

These rigging screws are ideal for a variety of uses and are particularly favoured for use with handrail wires and other general daily purposes.

Manufactured from marine grade stainless steel they offer resistance to rust and a high quality appearance that lasts.

Jaw and jaw terminals allow for quick and easy fitments to be made onto the rigging screw.